In the dynamic landscape of modern engineering, CNC machining has emerged as a revolutionary force, transforming the way we manufacture and design intricate components with unmatched precision. Australia has been a pioneer in the development of industrial automation and has seen CNC Mills replacing CNC Machines.

CNC machining uses the principle of subtractive manufacture that involves cutting out material rather than making it into precise components. CNC machines are at the heart of the technological advancement. They are an amazing feat of technology and the cornerstone for precision manufacturing.

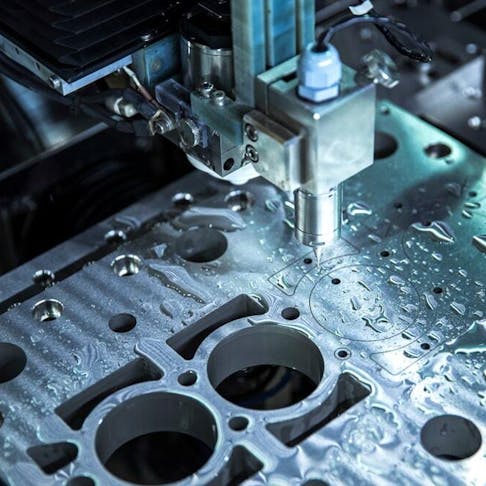

CNC Machines are controlled and directed by computer systems using digital technology which automate industrial machinery. The high-speed cutters of the CNC machine are guided by this code, which allows them to achieve the highest precision results while transforming solid material blocks into the desired forms. This synergy is most evident in larger industrial installations. It is a seamless integration of CNC Machines with computers increases productivity and efficiency.

The mechanisms involved the mechanics involved in CNC machining are complex and fascinating. Starting with a solid material block CNC Mills employ high-speed cutters to carve out the desired shape using meticulous details. CNC machining offers unparalleled precision. This is why it is the most preferred method in industries where precision and precision are paramount.

Australia’s CNC Machine scene is thriving. Modern technology and a thriving industrial sector are driving innovation. CNC Machine Australia is an innovation hub where industries like aerospace electronics, automotive and electronics rely on CNC machine tools to attain unbeatable accuracy and precision.

CNC Mills can play a critical part in shaping the manufacturing industry of the future. These machines, which are controlled by computer codes and create precise components for various industries, show flexibility. CNC Mills have become essential tools for engineers and manufacturers due to their effectiveness and accuracy.

CNC machining offers many advantages that surpass the limitations of traditional manufacturing. One of the most significant advantages is the capability to create complex and intricate parts with high precision. CNC Machines are digital, which allows for rapid prototyping, which cuts down on time and costs.

CNC Machine Tools contributes significantly to the efficiency in CNC machine machining. These tools include a wide variety of tools that are used to aid the machining process. They can be used to cut, shape, drilling or finishing. The combination of CNC Machines and CNC Machine Tools ensures a seamless workflow while maximising precision and minimizing waste.

CNC machining has been adopted by industries across the board for its transformative abilities. CNC machineries have a vital role in the aerospace sector where complex components are manufactured that require high precision and dependability. CNC machining is a highly efficient method of manufacturing intricate parts, like infrastructure and machinery.

CNC machineries have also demonstrated its versatility in the electronics and automotive industries. The intricate components needed in electronic devices as well as the precise requirements of automotive engineering find their match with the capabilities of CNC Machines. CNC machining’s versatility is evident in the many uses it has. From shaping electronic circuits to making engines, CNC machines are used to accomplish a variety of jobs.

In the end, CNC machining has redefined the landscape of modern manufacturing, with CNC Machines, CNC Mills as well as CNC Machine Tools standing as the pillars of the technological revolution. In Australia and beyond, the precision, efficiency, and versatility of CNC machining continue to shape the future of engineering, and paving the way to innovation and superiority in all industries it impacts.